Our CNC Milling Capabilities

For over three decades, Cootehill Precision Engineering has solidified its position as a leader in precision machining, demonstrating an unwavering commitment to excellence. The backbone of our success lies in our comprehensive range of CNC machines, which have been instrumental in crafting intricate components featuring complex geometric and freeform designs. This extensive experience, combined with cutting-edge technology, allows us to consistently deliver high-quality machined parts to meet the diverse needs of our customers.

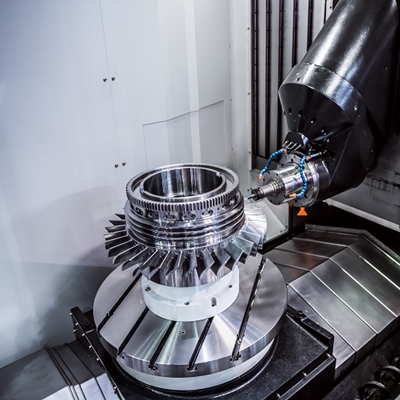

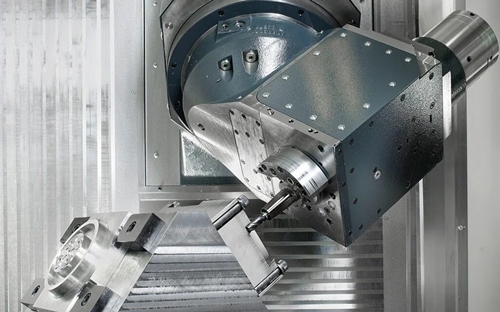

One of our standout features is the CNC Milling capabilities, which extend to full 5-axis machining. This advanced technology enables us to manufacture components with unparalleled precision and versatility. The ability to manipulate the tool in five different axes grants us the flexibility to tackle even the most intricate and challenging designs. Our commitment to staying at the forefront of machining technology ensures that we can meet the evolving demands of various industries.

In the realm of CNC Turning, our capabilities are equally impressive, covering components up to 3 meters in length. Furthermore, our high-speed small diameter capability sets us apart, allowing us to achieve remarkable precision even in the fabrication of smaller parts. This versatility enables us to cater to a wide spectrum of industries, from aerospace to medical, where precision is paramount.

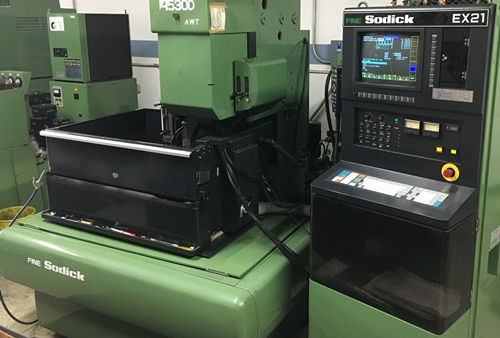

Adding another layer to our machining prowess is our Electrical Discharge Machining (EDM) capability. This technology enables us to conduct fine-detail profile machining in an extensive range of materials, including metals and carbides. EDM is particularly beneficial when working with materials that are challenging to machine using traditional methods. This capability opens up new possibilities for intricate and delicate components, meeting the demands of industries where precision and attention to detail are non-negotiable.

At Cootehill Precision Engineering, we recognize that staying ahead in the world of precision machining requires more than just cutting-edge technology. It demands a deep understanding of materials, an unwavering commitment to quality, and a dedication to continuous improvement. Our team of skilled professionals, coupled with our state-of-the-art facilities, positions us as a trusted partner for those seeking top-tier precision machining solutions. As we look to the future, we remain steadfast in our pursuit of excellence, ready to tackle new challenges and exceed the expectations of our valued customers.

Technical Specifications & Capacity Guide

| Machine | Axis | X-Axis | Y-Axis | Z-Axis | Misc |

|---|---|---|---|---|---|

| XYZ 2010 HD | 3 | 2000mm | 1000mm | 800mm | Max Table Load : 3000kg |

| JohnFord 3000 SHD-VMC | 3 | 3000mm | 1100mm | 800mm | Max Table Load : 4800kg |

| Doosan DNM 6700 | 4 | 1300mm | 670mm | 670mm | 4 Axis Capacity ,Max Table Load:1200kg |

| Kitimura Mycenter 6 VMC | 4 | 1220mm | 610mm | 610mm | 4 Axis Capacity ⌀430 Swing Diameter |

| Quaser | 3 | 1000mm | 600mm | 600mm | Max Table Load : 1000kg |

| Tryax VMC | 4 | 800mm | 400mm | 200mm | 4 Axis Capacity: Driving Head Chuck ⌀250 |

| AXILE G8 | 5 | 670mm | 820mm | 600mm | A-120/+120°, C-360° |

| Machine | Chuck Capacity | Additional info |

|---|---|---|

| HYUNDAI WIA L400 LMC | Chuck Capacity ⌀400mm X 2100mm | |

| Webstar and Bennett (VTL) | Chuck Capacity ⌀400mm X 2100mm | Max Swing 1525mm Max Height 1200mm |

| Doosan Puma 3100LY | Chuck Capacity ⌀400mm X 1500mm | Y- axis Capacity |

| PINACHO MUSTANG 200 | Chuck Capacity ⌀250mm | |

| COLCHESTEOR TORNADO 300 | Chuck Capacity ⌀250 X 1000mm | |

| HYUNDAI HIT 15S | Bar Feed Capacity ⌀40mm X 1000mm | |

| DUGARD EAGLE 200 | Bar Feed Capacity ⌀50mm X 1000mm | |

| PINACHO CNC Lathe | Chuck Capacity ⌀250mm | |

| Lynx 300 | Chuck Capacity 450mm X 765mm | |

| Mazak Cybertech Turn 4500 | Chuck Capacity 810mm X 3048mm | Also offers deep hole boring with an automatic changer capable of boring 1 metre |

| Machine | Quantity |

|---|---|

| Bridge Port Mill 3 Axis Mill | 3 off |

- Capacity ⌀3mm – ⌀600mm, 560mm swing (3 Off)

- Large Turning Capacity: ⌀1500mm x 350mm, D.B.C – 3m (1 Off)

- Large Turning Capacity: ⌀600mm, 840mm swing, D.B.C – 3.5m (1 Off)

| Machine | Capacity |

|---|---|

| Fine Sodick A530D | Table Travel ( X and Y) (mm) – 500 x 320

Z Axis Travel (mm) – 270/5 to 275 Sub Table Travel (U and V) (mm) – 50 x 50 Max. Workpiece Dimensions (X / Y / Z) – 900 x 700 x 260/180 (/submerged) Maximum Workpiece Weight (kg) – 500/350 (/submerged) Taper Angle (degrees) – ±10°/100 Wire Diameter (mm) – 0.1 to 0.3 |